What is "Textured Yarn" - Definition & Explanation

Last Updated on: 09-Apr-2023 (1 year, 18 days ago)

Share on Facebook • Share on Twitter

Last Updated on: 09-Apr-2023 (1 year, 18 days ago)

Share on Facebook • Share on Twitter

Textured Yarn

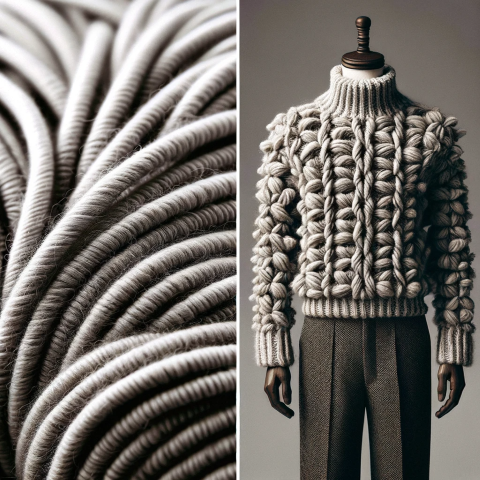

�Textured yarn is a type of yarn that is created by modifying the surface of the yarn in some way, which gives it a distinctive texture or feel. This can be achieved through a number of different techniques, including twisting, crimping, or heat setting.

One of the most common methods of creating textured yarn is by twisting. In this process, the yarn is twisted in a way that creates irregularities in the surface of the yarn. This can be done using a variety of different techniques, such as twisting the yarn at different intervals or using different types of twist. The result is a yarn with a rough, uneven surface that has a more interesting texture than a smooth, uniform yarn.

Another way to create textured yarn is by crimping. In this process, the yarn is put through a machine that compresses and stretches it in a way that creates waves or curls in the fibers. This can be done with synthetic or natural fibers, and can create a range of different textures depending on the degree of crimping.

Heat setting is another common method of creating textured yarn. In this process, the yarn is exposed to heat in order to change its physical properties. This can be done by passing the yarn through a heated chamber, or by using a special type of yarn that is designed to respond to heat. The result is a yarn with a more rigid texture that holds its shape better.

Textured yarn can be used for a variety of different purposes in textile production. For example, it can be used to create more interesting and complex patterns in woven or knitted fabrics. It can also be used to add more depth and dimension to fabrics that would otherwise be flat and uninteresting.

One of the advantages of using textured yarn is that it can be used to create a wide range of different effects. For example, a yarn with a highly twisted surface might be used to create a fabric with a more rough, rustic feel, while a yarn with a more uniform crimp might be used to create a fabric with a more subtle, elegant texture.

Another advantage of textured yarn is that it can help to improve the performance of certain types of fabrics. For example, a yarn with a crimped surface might be used to create a fabric with better insulation properties, as the crimped fibers help to trap air and retain heat. Similarly, a yarn with a heat-set surface might be used to create a fabric that is more resistant to wrinkling or stretching.

Textured yarn can be made from a variety of different fibers, including both natural and synthetic materials. Common fibers used for textured yarns include wool, cotton, silk, nylon, and polyester. Different fibers will have different properties, such as strength, elasticity, or absorbency, which can affect the performance of the final product.

In addition to the different methods of creating textured yarn, there are also different types of textured yarn. Some textured yarns have a consistent texture throughout the length of the yarn, while others have sections of textured yarn interspersed with sections of smoother yarn. Some textured yarns are also designed to change texture when exposed to different temperatures or other environmental factors.

Overall, textured yarn is a versatile and useful material for textile production. It can be used to create a wide range of different textures and effects, and can be made from a variety of different fibers. Whether used for fashion, home decor, or industrial applications, textured yarn can help to add interest, dimension, and functionality to a variety of different fabrics and products.

One of the most common methods of creating textured yarn is by twisting. In this process, the yarn is twisted in a way that creates irregularities in the surface of the yarn. This can be done using a variety of different techniques, such as twisting the yarn at different intervals or using different types of twist. The result is a yarn with a rough, uneven surface that has a more interesting texture than a smooth, uniform yarn.

Another way to create textured yarn is by crimping. In this process, the yarn is put through a machine that compresses and stretches it in a way that creates waves or curls in the fibers. This can be done with synthetic or natural fibers, and can create a range of different textures depending on the degree of crimping.

Heat setting is another common method of creating textured yarn. In this process, the yarn is exposed to heat in order to change its physical properties. This can be done by passing the yarn through a heated chamber, or by using a special type of yarn that is designed to respond to heat. The result is a yarn with a more rigid texture that holds its shape better.

Textured yarn can be used for a variety of different purposes in textile production. For example, it can be used to create more interesting and complex patterns in woven or knitted fabrics. It can also be used to add more depth and dimension to fabrics that would otherwise be flat and uninteresting.

One of the advantages of using textured yarn is that it can be used to create a wide range of different effects. For example, a yarn with a highly twisted surface might be used to create a fabric with a more rough, rustic feel, while a yarn with a more uniform crimp might be used to create a fabric with a more subtle, elegant texture.

Another advantage of textured yarn is that it can help to improve the performance of certain types of fabrics. For example, a yarn with a crimped surface might be used to create a fabric with better insulation properties, as the crimped fibers help to trap air and retain heat. Similarly, a yarn with a heat-set surface might be used to create a fabric that is more resistant to wrinkling or stretching.

Textured yarn can be made from a variety of different fibers, including both natural and synthetic materials. Common fibers used for textured yarns include wool, cotton, silk, nylon, and polyester. Different fibers will have different properties, such as strength, elasticity, or absorbency, which can affect the performance of the final product.

In addition to the different methods of creating textured yarn, there are also different types of textured yarn. Some textured yarns have a consistent texture throughout the length of the yarn, while others have sections of textured yarn interspersed with sections of smoother yarn. Some textured yarns are also designed to change texture when exposed to different temperatures or other environmental factors.

Overall, textured yarn is a versatile and useful material for textile production. It can be used to create a wide range of different textures and effects, and can be made from a variety of different fibers. Whether used for fashion, home decor, or industrial applications, textured yarn can help to add interest, dimension, and functionality to a variety of different fabrics and products.

Textured Yarn

A continuous filament yarn that has been processed to introduce durable crimps, coils, loops or other fine distortions along the lengths of the filaments.

A continuous filament yarn that has been processed to introduce durable crimps, coils, loops or other fine distortions along the lengths of the filaments.

Textured Yarn

A yarn that has been so processed as to introduce durable crimps (q.v.), coils, loops or other fine distortions along the length of the fibres or filaments.

NOTE:

a) The main texturing processes usually applied to continuous-filament yarns made from or containing thermoplastic fibres, are as follows:

1. The yarn is highly twisted, heat-set and untwisted, either as a continuous process (false twisting) or as a three-stage process.

2. The yarn is passed through a heated "stuffer box" (stuffer box crimping).

3. The heated yarn is passed over a knife edge (edge crimping).

4. The heated yarn is passed between a pair of geared wheels or some similar device (gear crimping).

5. The yarn is knitted into a fabric, heat-set and unravelled (knit-deknit).

6. Loops are formed in individual filaments by over-feeding into a turbulent airstream (air-textured).

7. Bicomponent Fibres (q.v.) are differentially shrunk.

b) Processes (1) and (3) above produce yarns of a generally high stretch character. This stretch character is frequently reduced by reheating the yarn in a state where it is only partly relaxed from the fully extended condition, thus producing a yarn with the bulkiness little reduced but with a much reduced retractive power.

c) Fabrics that contain textured yarns have increased bulk, opacity, and moisture absorbency and improved thermal insulation properties with a warmer handle (q.v.); some textured yarns also confer extensible or "stretch" properties on fabrics made from them.

A yarn that has been so processed as to introduce durable crimps (q.v.), coils, loops or other fine distortions along the length of the fibres or filaments.

NOTE:

a) The main texturing processes usually applied to continuous-filament yarns made from or containing thermoplastic fibres, are as follows:

1. The yarn is highly twisted, heat-set and untwisted, either as a continuous process (false twisting) or as a three-stage process.

2. The yarn is passed through a heated "stuffer box" (stuffer box crimping).

3. The heated yarn is passed over a knife edge (edge crimping).

4. The heated yarn is passed between a pair of geared wheels or some similar device (gear crimping).

5. The yarn is knitted into a fabric, heat-set and unravelled (knit-deknit).

6. Loops are formed in individual filaments by over-feeding into a turbulent airstream (air-textured).

7. Bicomponent Fibres (q.v.) are differentially shrunk.

b) Processes (1) and (3) above produce yarns of a generally high stretch character. This stretch character is frequently reduced by reheating the yarn in a state where it is only partly relaxed from the fully extended condition, thus producing a yarn with the bulkiness little reduced but with a much reduced retractive power.

c) Fabrics that contain textured yarns have increased bulk, opacity, and moisture absorbency and improved thermal insulation properties with a warmer handle (q.v.); some textured yarns also confer extensible or "stretch" properties on fabrics made from them.

Textured Yarn

a general classification for continuous filament man - made fibre yarn which have been treated to give them hand and appearance which is different from the untreated yarn and / or stretchy. These yarns in some cases exhibit spun yarn effect. The yarns may be crimped ,curled, coiled, distorted through air jet process or given a false twist and then be heat set.

a general classification for continuous filament man - made fibre yarn which have been treated to give them hand and appearance which is different from the untreated yarn and / or stretchy. These yarns in some cases exhibit spun yarn effect. The yarns may be crimped ,curled, coiled, distorted through air jet process or given a false twist and then be heat set.

Some other terms

Some more terms:

Sanded

35

A finishing process that brings the fabric in contact with sandpaper or another abrasive material. This may be done to raise surface fiber, impart a peached or sueded hand or to create a surface...

Electret

32

A non-conductive polymeric material which can maintain a long-lived electrostatic charge. Polypropylene electret filtration fabrics conveniently combine the mechanical removal of particles with an...

Melt-spinning

104

Some polymeric fibres are spun by melting the polymer to a liquid state. The liquid is forced through the spinner opening under pressure and cooled by a jet of air to form the filament. Nylon can be...

China Silk

49

China silk is a plain weave silk of various weights. This silk is the "hand" or touch that many people identify as silk. There are various weights of China silk from light, used for linings and many...

Haute Couture

630

Haute couture (French for 'high sewing') is a common term for high fashion as produced in Paris and imitated in other fashion capitals such as New York, London, and Milan. Sometimes it is used only...

Add a definition

Add a definition for a textile term that you know about! Send us an email & tell us:

- The term you want to define

- Its definition in 500 words or less

- Attach an image if necessary.

- Optionally, tell us about yourself in 200 words or less!

Companies for Textured Yarn:

If you manufacture, distribute or otherwise deal in Textured Yarn, please fill your company details below so that we can list your company for FREE! Send us the following details:

- Company name

- Company address

- Attach a logo, if necessary.

- Optionally, tell us about yourself in 200 words or less!

(s) 2024 TextileGlossary.com Some rights reserved. • Sitemap