Last Updated on: 12-Jun-2024 (1 month, 15 days ago)

Share on Facebook • Share on Twitter

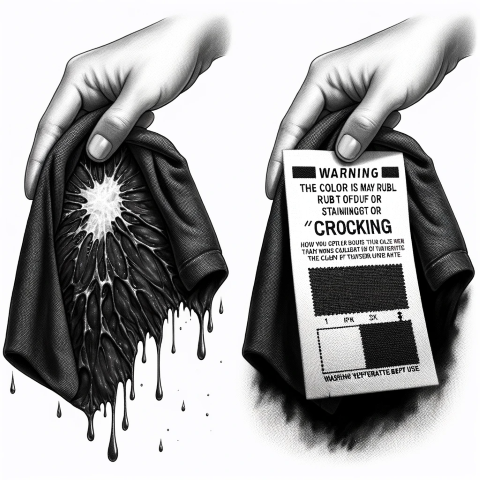

The term "crocking" comes from the old English word "crock" which means "to rub," and it is used to describe the process by which dyes and pigments can be easily rubbed off of fabrics onto other surfaces. This can result in unsightly stains and discoloration on clothing, upholstery, and other textile products.

There are several factors that can contribute to crocking, including the type of dye or pigment used, the quality of the fabric, and the method of production. Certain types of dyes, such as direct dyes, are more prone to crocking than others, such as reactive dyes, which are designed to bond more tightly to the fibers of the fabric.

The quality of the fabric can also play a role in crocking. Fabrics that are loosely woven or have a low thread count are more likely to experience crocking because the fibers are more prone to friction and abrasion. In addition, fabrics that have been treated with certain finishes, such as softeners or water repellents, can be more prone to crocking because these finishes can interfere with the bonding of the dye to the fibers.

Finally, the method of production can also impact crocking. For example, fabrics that are printed using screen printing or roller printing techniques are more prone to crocking because the dye is only applied to the surface of the fabric and is not able to penetrate deeply into the fibers. In contrast, fabrics that are dyed using a continuous dyeing process are less prone to crocking because the dye is able to penetrate deeply into the fibers, creating a more durable bond.

There are several methods that can be used to reduce the risk of crocking in textiles. One of the most effective methods is to use high-quality dyes and pigments that are designed to bond tightly to the fibers of the fabric. Additionally, fabrics can be pre-treated with finishes that help to increase the bond between the dye and the fibers, such as alkaline solutions or cationic dyes.

Another method for reducing crocking is to use a finishing process that helps to seal the dye into the fabric. This can be done by applying a resin or coating to the fabric that helps to prevent the dye from rubbing off onto other surfaces.

In conclusion, crocking is a common problem in textiles that occurs when dyes or pigments rub off or transfer onto other surfaces. It can be caused by a variety of factors, including the type of dye or pigment used, the quality of the fabric, and the method of production. To reduce the risk of crocking, high-quality dyes and pigments should be used, fabrics should be pre-treated with finishes to increase the bond between the dye and the fibers, and a finishing process should be used to seal the dye into the fabric.

The removal of dye from a fabric by rubbing. Crocking can be caused by insufficient dye penetration or fixation, the use of improper dyes or dyeing methods, or insufficient washing and treatment after the dyeing operation. Crocking can occur under dry or wet conditions.

Some more terms:

Bi Component Fibres

Fibres spun from two different polymers. The most common types are made from polymers which have different melting points and are used for thermal bonding. Another variant is produced from polymers...

Read about Bi Component FibresPadding

Padding is the material that goes on directly under your upholstery fabric. Its function is to fill out and firm up the contours of the sofa or chair (fully upholstered) so that the fabric sits...

Read about PaddingThe Tapestry of Woven Fabric: History, Types, and Applications

A woven is a cloth formed by weaving. It only stretches in the bias directions (between the warp and weft directions), unless the threads are elastic. Woven cloth usually frays at the edges, unless...

Read about WovenFaux

French for "false" can be anything made to simulate something that it's not. Examples: Faux graining (painting grain lines on figureless wood), faux suede (non-leather fabric made to simulate suede...

Read about FauxPurl Stitch

The purl stitch is a fundamental technique in knitting that creates a raised, textured pattern on the fabric. It is commonly used to add depth, contrast, and variety to knitted garments, accessories,...

Read about Purl StitchFaux silk

Faux silk, also known as artificial silk or synthetic silk, is a type of fabric designed to mimic the appearance and texture of natural silk, but it is made from synthetic fibers instead. It offers a...

Read about Faux silkAlcohol, denatured

Solvent for shellac products, will not thin most other coatings. Can be dissolved in water for cleaning. Can be used in alcohol type stoves and chafing dishes. Ethanol is available as denatured...

Read about Alcohol, denaturedMarseilles

Named after it's city of origin in France. It is identified by its raised woven pattern. This double-faced textile has a quilted appearance that is very elegant. Usually found in white, but other...

Read about MarseillesAdd a definition

- The term you want to define

- Its definition in 500 words or less

- Attach an image if necessary.

- Optionally, tell us about yourself in 200 words or less!

Companies for Crocking:

- Company name

- Company address

- Attach a logo, if necessary.

- Optionally, tell us about yourself in 200 words or less!

Chiffon, a lightweight, sheer fabric, is often made from silk or synthetic fibers.

Chiffon, a lightweight, sheer fabric, is often made from silk or synthetic fibers.