Last Updated on: 17-Mar-2024 (4 months, 10 days ago)

Share on Facebook • Share on Twitter

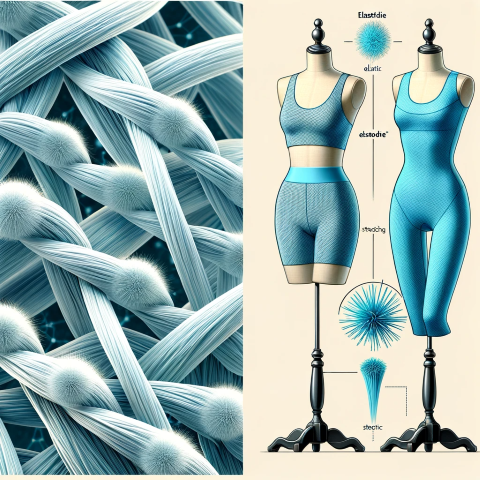

Elastodiene Fibres: Exploring the Elastic Marvels

Elastodiene Fibre: Exploring Innovation in Textile

Elastodiene fiber is a remarkable textile material known for its exceptional elasticity and durability. Developed through innovative manufacturing processes, elastodiene fibers offer unique properties that make them suitable for a wide range of applications. In this comprehensive article, we will delve into the meaning, types, handling tips, and profiles of top international users and manufacturers of elastodiene fiber.

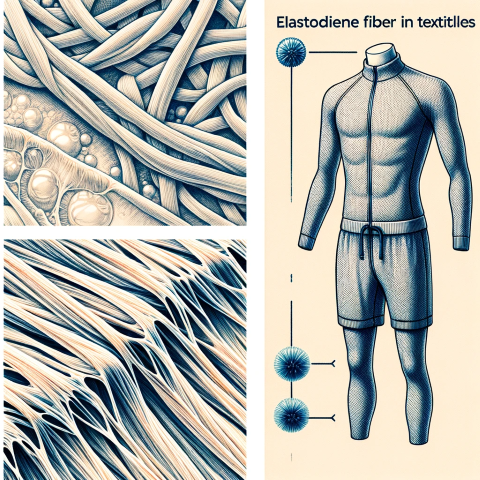

Elastodiene fiber is a synthetic fiber made from elastomeric polymers, specifically diene-based monomers. These fibers possess remarkable elasticity, allowing them to stretch significantly and recover their original shape upon release of tension. Elastodiene fibers exhibit excellent resistance to abrasion, chemicals, and UV radiation, making them ideal for applications that require flexibility and durability.

There are several types of elastodiene fibers, each with unique properties and applications:

- Styrene Butadiene Rubber (SBR): SBR fibers are widely used in the production of tire cords, conveyor belts, and industrial fabrics. They offer excellent resistance to wear, high tensile strength, and good adhesion to various materials.

- Polybutadiene (BR): BR fibers are known for their high elasticity and low-temperature flexibility. They are commonly used in the manufacturing of elastic bands, sportswear, and medical textiles.

- Nitrile Rubber (NBR): NBR fibers combine excellent oil resistance with flexibility and high tensile strength. They are extensively utilized in the production of hoses, seals, and protective clothing.

- Chloroprene Rubber (CR): CR fibers exhibit exceptional resistance to chemicals, heat, and weathering. They are commonly used in applications such as wetsuits, diving gear, and outdoor fabrics.

Tips for Handling Elastodiene Fibers

Proper handling and care are essential to maximize the performance and lifespan of elastodiene fibers:

- Storage Conditions: Store elastodiene fibers in a cool, dry place away from direct sunlight to prevent degradation and loss of elasticity.

- Avoid Extreme Temperatures: Protect elastodiene fibers from excessive heat or cold, as extreme temperatures can affect their elasticity and mechanical properties.

- Gentle Washing: When laundering garments or textiles made from elastodiene fibers, use a gentle cycle and mild detergent to avoid damage or loss of elasticity.

- Avoid Harsh Chemicals: Elastodiene fibers are susceptible to damage from harsh chemicals, so it is important to avoid exposure to solvents, bleach, or strong acids.

Top International Users and Manufacturers

Elastodiene fibers are utilized by several prominent international brands in the textile industry. Here are profiles of some of the top users and manufacturers:

- Goodyear: Goodyear, a renowned tire manufacturing company, utilizes elastodiene fibers, particularly SBR, in the production of high-performance tire cords. Their commitment to innovation and quality has established them as a global leader in the industry.

- Asics: Asics, a leading athletic footwear and apparel brand, incorporates elastodiene fibers in their sportswear to provide flexibility, support, and durability. Their innovative designs and use of advanced materials have made them a preferred choice among athletes worldwide.

- W.L. Gore & Associates: Gore is a well-known manufacturer of high-performance technical fabrics, including elastodiene fibers. Their products find applications in industries such as aerospace, outdoor apparel, and healthcare, offering exceptional performance in demanding environments.

- Trinseo: Trinseo is a global materials solutions provider that manufactures elastodiene fibers for various industries, including automotive, construction, and consumer goods. Their commitment to sustainability and product innovation has positioned them as a trusted supplier in the market.

- Lion Elastomers: Lion Elastomers is a leading manufacturer of synthetic rubber, including elastodiene fibers. Their diverse product portfolio caters to industries such as automotive, electrical, and industrial, delivering high-quality solutions for specific application requirements.

Elastodiene fiber represents a remarkable advancement in the textile industry, offering exceptional elasticity, durability, and versatility. With its diverse range of applications and continuous innovation by top international users and manufacturers, elastodiene fiber continues to revolutionize various sectors, including automotive, sports, and industrial textiles. By understanding the meaning, types, and proper handling tips associated with elastodiene fiber, professionals and enthusiasts alike can harness its unique properties to drive further advancements in textile technology.

Watch Video about: Elastodiene Fibres

�Elastodiene fiber is a type of synthetic fiber that is used primarily in the production of rubber-based products. This fiber is made from elastomers, which are polymers that have elastic properties. Elastomers are commonly used in the production of rubber products, but elastodiene fibers provide additional benefits, such as increased strength and flexibility.

Elastodiene fibers are produced by spinning elastomers into fibers, which are then twisted or spun into yarns. The resulting fibers have a high level of elasticity, making them ideal for use in applications where flexibility is important. Elastodiene fibers are commonly used in the production of clothing, particularly athletic wear, due to their stretchiness and ability to wick away moisture.

One of the primary benefits of elastodiene fibers is their ability to withstand high levels of stress without breaking. This makes them ideal for use in applications such as tires, where they are able to withstand the weight of heavy vehicles and maintain their shape over time. Elastodiene fibers are also resistant to abrasion and wear, making them a popular choice for industrial applications such as conveyor belts and hoses.

In addition to their strength and flexibility, elastodiene fibers also offer a high degree of chemical resistance. This makes them ideal for use in environments where exposure to chemicals is common, such as in the production of medical devices and pharmaceuticals.

One of the most common elastodiene fibers is spandex, which is commonly used in the production of athletic wear and other clothing items. Spandex is a highly elastic fiber that is able to stretch up to 600% of its original length without breaking. This makes it ideal for use in applications such as compression garments, which provide support and compression to muscles during exercise.

Other types of elastodiene fibers include butadiene rubber and styrene-butadiene rubber, both of which are commonly used in the production of tires and other industrial products.

Overall, elastodiene fibers offer a wide range of benefits and are commonly used in a variety of applications, from clothing to industrial products. Their strength, flexibility, and chemical resistance make them an ideal choice for applications where durability is key. As technology continues to advance, it is likely that elastodiene fibers will continue to play an important role in the production of new and innovative products.

Some more terms:

Fabric Construction

Introduction to Fabric Construction Fabric construction is a fundamental aspect of textile engineering, involving various methods and techniques to create fabrics with specific properties and...

Read about Fabric ConstructionReed

A toothed, comb-like part of a LOOM. Its function is to hold the strands of longitudinal yarn (WARP) in alignment between its teeth and also to push each transverse thread (PICK) tight against the...

Read about ReedNainsook

A fine, lightweight cotton in a plain weave that is produced in the finishing processes from the same gray goods as used for batiste, cambric, lawn. Soft and has a slight luster in the better...

Read about NainsookSanforize Pucker

Results from uneven wetting out on sanforize; usually caused by defective spray heads. Fabric will appear wavy or puckering when spread on cutting table. Difficult to detect while inspecting on...

Read about Sanforize PuckerHammered Satin

Hammered satin is a type of textile that features a distinctive surface texture, created by a special finishing technique that compresses the fabric in a way that produces a puckered or dimpled...

Read about Hammered SatinAngora Merino Rayon

A true exotic yarn for the hills of Peru. It's an intimate blend of 40% Angora / 40% Merino / 20% Rayon. This three-ply 2200 yds/lb yarn should be used for that special garment where a soft luxurious...

Read about Angora Merino RayonSuper

The Super grading system is used to grade the quality of wool fabric. The higher the number, the more yarn is packed in per square inch, therefore all things being equal a super 120s yarn is better...

Read about SuperILD

Indentation Load Deflection (ILD) refers to the firmness of a piece of foam. The lab puts a 4" x 15" x 15" piece of foam on a flat surface. Then a round metal plate, 8" in diameter, pushes down on...

Read about ILDOn this page

Add a definition

- The term you want to define

- Its definition in 500 words or less

- Attach an image if necessary.

- Optionally, tell us about yourself in 200 words or less!

Companies for Elastodiene Fibres:

- Company name

- Company address

- Attach a logo, if necessary.

- Optionally, tell us about yourself in 200 words or less!

Fashion designer Giles Deacon is known for his theatrical runway shows and elaborate designs.

Fashion designer Giles Deacon is known for his theatrical runway shows and elaborate designs.