Last Updated on: 11-Feb-2024 (5 months, 16 days ago)

Share on Facebook • Share on Twitter

Shelf Bra Revelations: From History to Modern-Day Applications

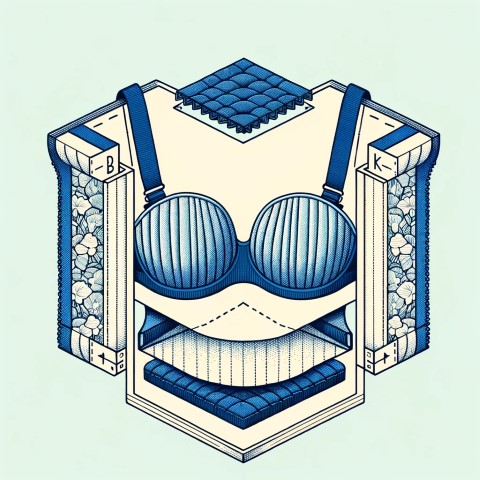

Exploring the Ingenious Shelf Bra: A Textile Marvel

The shelf bra, a remarkable innovation in textile engineering, stands as a testament to the ingenuity and versatility of fabric design. Originating from the intimate apparel sector, the shelf bra has transcended its conventional boundaries to become a staple in various garments, offering both support and comfort.

Unlike traditional bras, the shelf bra is seamlessly integrated into clothing, featuring a built-in elastic band or underwire that provides gentle support to the bust without the need for separate undergarments. This unique design not only enhances the aesthetic appeal of clothing but also eliminates the discomfort often associated with wearing conventional bras.

The evolution of the shelf bra has been marked by advancements in textile technology, enabling the creation of fabrics with exceptional stretch, breathability, and moisture-wicking properties. From athletic wear to formal attire, the shelf bra has found its place in a diverse range of garments, catering to the needs of modern consumers.

In this article, we will delve into the intricacies of the shelf bra, exploring its history, types, applications, and maintenance tips. Through a comprehensive analysis, we aim to unveil the transformative impact of the shelf bra on the textile industry and its enduring relevance in contemporary fashion.

Brief History and Types of Shelf Bras

The shelf bra, also known as a balconette bra or open-cup bra, has a fascinating history rooted in lingerie design. Initially introduced as an alternative to traditional bras, the shelf bra has evolved over time to cater to various preferences and needs. Here are some common types:

- Basic Shelf Bra: The basic shelf bra features a band-like structure under the bust, providing minimal coverage and support while enhancing cleavage.

- Padded Shelf Bra: This type of shelf bra incorporates padding or molded cups to add volume and shape to the bust, offering a more defined silhouette.

- Lace Shelf Bra: With intricate lace detailing, the lace shelf bra combines elegance with functionality, making it suitable for both everyday wear and special occasions.

- Sports Shelf Bra: Designed for active lifestyles, the sports shelf bra offers enhanced support and comfort during workouts, featuring moisture-wicking fabrics and reinforced seams.

When it comes to handling and maintaining shelf bras, there are several tips to keep in mind to ensure longevity and optimal performance:

- Hand Wash: To preserve the fabric and elastic integrity, it's recommended to hand wash shelf bras using a mild detergent and lukewarm water.

- Air Dry: Avoid using a dryer as it can damage the elastic and shape of the bra. Instead, gently squeeze out excess water and allow the bra to air dry flat.

- Store Carefully: Store shelf bras flat or folded in a lingerie drawer to prevent misshaping or stretching. Avoid hanging them by straps, as this can lead to distortion.

- Rotate Bras: Rotate between multiple shelf bras to prevent excessive wear and tear on a single bra. This helps maintain their elasticity and shape over time.

Applications of Shelf Bra in Textiles

Shelf bras, with their unique design and functionality, find applications in various textile products, catering to different needs and preferences. Here are some common applications:

- Lingerie: Shelf bras are widely used in lingerie, providing support and shaping without the need for full coverage. They are popular in bras, camisoles, and babydolls, offering a flattering silhouette and enhancing cleavage.

- Swimwear: In swimwear, shelf bras are incorporated into bikini tops and one-piece swimsuits to provide support and structure. They offer a comfortable alternative to underwire bras and are suitable for both leisure and active swimming.

- Activewear: Shelf bras are integrated into activewear tops and tanks, offering support during workouts and yoga sessions. They provide compression and stability, allowing for freedom of movement while maintaining a sleek silhouette.

- Fashion Apparel: Fashion designers often incorporate shelf bras into tops and dresses to create unique styles and silhouettes. They add dimension and structure to garments, enhancing the overall look and feel.

- Medical Garments: Shelf bras are used in medical garments such as post-surgery bras and mastectomy camisoles. They provide gentle support and comfort during the healing process, promoting recovery and well-being.

Overall, the versatility and functionality of shelf bras make them a valuable component in various textile applications, offering support, shaping, and comfort across different industries and consumer preferences.

Detailed Profiles of Major Manufacturers or Users of Shelf Bra in Textiles

- Victoria's Secret: Renowned for its lingerie and swimwear collections, Victoria's Secret offers a wide range of products featuring shelf bras. With a focus on fashion-forward designs and high-quality materials, Victoria's Secret remains a prominent player in the intimate apparel industry.

- Calvin Klein: Calvin Klein, known for its iconic underwear and loungewear, incorporates shelf bras into its bralette and camisole designs. The brand's minimalist aesthetic and emphasis on comfort make it a popular choice among consumers seeking functional yet stylish undergarments.

- Natori: Natori, founded by designer Josie Natori, specializes in luxury lingerie and loungewear. The brand's shelf bra styles feature intricate lace details and innovative design elements, catering to discerning customers looking for elegance and sophistication.

- Lululemon: Lululemon, a leading activewear brand, offers shelf bra tops and tanks designed for yoga, fitness, and athleisure wear. Known for its technical fabrics and performance-driven designs, Lululemon provides supportive and breathable options for active individuals.

- Freya: Freya, a lingerie brand under the Wacoal Europe umbrella, focuses on offering supportive and stylish undergarments for full-busted women. Their shelf bra styles combine fashion and function, providing comfort and confidence for women of all shapes and sizes.

- HerRoom: HerRoom, an online retailer specializing in intimate apparel, features a diverse selection of shelf bra products from various brands. With a focus on inclusivity and comprehensive sizing options, HerRoom caters to a wide range of customers seeking comfortable and supportive undergarments.

Conclusion: Unveiling the Supportive Tapestry of Shelf Bras

The journey through the intricacies of shelf bras reveals a tapestry woven with comfort, support, and style. From its historical roots to its modern-day applications, the shelf bra stands as a testament to the evolution of lingerie in the textile industry.

As we explore the various types and applications, it becomes evident that the shelf bra is not merely a functional undergarment but a symbol of empowerment and self-expression. Whether providing discreet support under everyday attire or enhancing confidence in athletic pursuits, shelf bras cater to diverse needs and preferences.

With tips for selecting and caring for shelf bras, wearers can ensure longevity and optimal performance. Proper handling and maintenance prolong the lifespan of these garments, ensuring continued comfort and support.

Profiles of major manufacturers and users shed light on the industry's key players, each contributing to the innovation and accessibility of shelf bras. From renowned brands to specialized retailers, a myriad of options exists for consumers seeking quality and reliability.

In conclusion, the shelf bra embodies the convergence of functionality and fashion, offering wearers the support they need without compromising on style. As lingerie continues to evolve alongside changing trends and technological advancements, the shelf bra remains a staple in the modern wardrobe, providing comfort, confidence, and empowerment.

An underwire bra with little or no cups. This bra will support your breasts while displaying most of your breast including your nipples. View HerRoom's selection of shelf bras.

Some more terms:

Cross Dyeing: The Textile Industry's Colour Mixing Masterstroke

Understanding Cross Dyeing: An OverviewDyeing is a time-honoured practice in the textile industry, instrumental in creating textiles of varied hues and patterns. Among the many dyeing techniques...

Read about Cross DyeingSponging

A pre-shrinkage process which involves the dampening with a sponge to woolen and worsted fabrics. The process is accomplished by rolling in moist muslin, or by steaming. This procedure is performed...

Read about SpongingChrome-free tanning

Chrome-free tanning is the tanning of hides to create leather either through the use of oils or natural tannins instead of chromium salts. This tanning process is more time intensive than chrome...

Read about Chrome-free tanningDacca Muslin

Dacca Muslin, also known as Dhaka Muslin, is a legendary fabric with a rich history and exceptional craftsmanship. Renowned for its delicate texture, sheer fineness, and intricate weaving, Dacca...

Read about Dacca MuslinCap Sleeve

Cap sleeves are a popular style of sleeve in textile design that is commonly used in women's clothing. This sleeve style is characterized by its short length, which extends only slightly over the...

Read about Cap SleeveMicrofleece

A lightweight, double-sided micro-fiber fleece noted for its outstanding low pill velour face, stretch, and chamois-like softness. It is commonly used for the interior portion of diapers because of...

Read about MicrofleeceDimensional stability

Results when a fiber or fabric will neither stretch or shrink. Relaxation shrinkage is when fibers, when elongated during weaving or finishing relax to their natural size after being washed....

Read about Dimensional stabilityCrettone

Made from cotton, linen, rayon in a plain or twill weave. Quality and price vary a great deal. The warp counts are finer than the filling counts which are spun rather loose. Strong substantial and...

Read about CrettoneOn this page

Add a definition

- The term you want to define

- Its definition in 500 words or less

- Attach an image if necessary.

- Optionally, tell us about yourself in 200 words or less!

Companies for Shelf Bra:

- Company name

- Company address

- Attach a logo, if necessary.

- Optionally, tell us about yourself in 200 words or less!

Vietnam is one of the top textile and garment exporters in the world.

Vietnam is one of the top textile and garment exporters in the world.