Last Updated on: 19-Mar-2024 (4 months, 8 days ago)

Share on Facebook • Share on Twitter

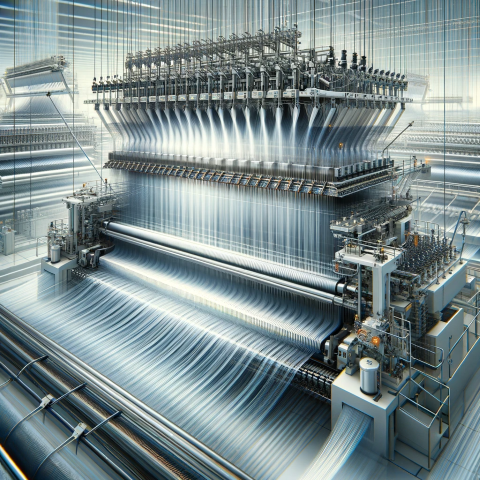

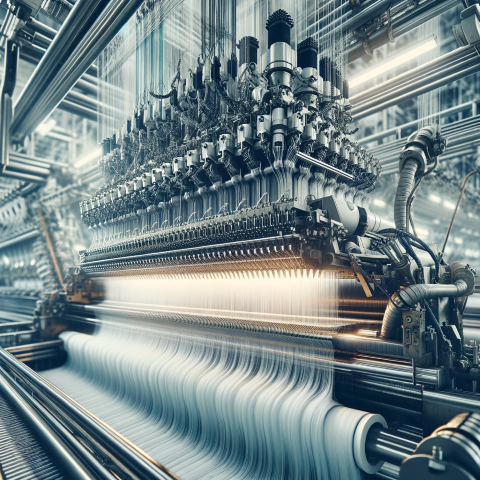

Exploring Air Jet Loom: A Textile Industry Game-Changer

The Evolution and Impact of Air Jet Looms in the Textile Industry

The inception of air jet looms marks a significant chapter in the textile industry, revolutionizing fabric production. Emerging in the 1950s, air jet looms utilized compressed air to propel the weft yarn across the shed, greatly enhancing speed and efficiency compared to traditional weaving methods. This technology evolved from the earlier shuttle and rapier looms, offering unparalleled speed and precision in fabric production.

Cam Air Jet Looms Design and Function: Equipped with a cam shedding mechanism, controlling heald frames for simple weave patterns.

Applications: Ideal for plain weaves and fabrics with basic designs, focusing on standard, high-volume production.

Advantages: Economical and less complex, offering reliability and ease of maintenance for standard fabric types.

Dobby Air Jet Looms

Design and Function: Uses a dobby shedding mechanism to control a large number of heald frames, enabling complex weave patterns.

Applications: Versatile for intricate twills, satins, and complex weaves, accommodating a variety of fabric designs.

Advantages: Offers greater flexibility in design and pattern creation, suitable for diverse fabric types.

Jacquard Air Jet Looms

Design and Function: Equipped with a Jacquard machine that controls each warp yarn individually for intricate designs.

Applications: Predominantly used for high-end, luxury fabrics like brocades, damasks, and tapestries.

Advantages: Unparalleled in design complexity, essential for producing premium, designer fabrics.

High-Speed Air Jet Looms

Design and Function: Engineered for high-speed operation, maximizing productivity with advanced features.

Applications: Ideal for mass production of standard fabrics like shirting, bedding, and drapery materials.

Advantages: High speed results in increased output, cost-effective for large-scale production.

Wide-Width Air Jet Looms

Design and Function: Designed to produce wider fabric rolls, handling broader fabric dimensions.

Applications: Suitable for large-scale fabrics like bed sheets, tablecloths, and other home textiles.

Advantages: Ensures consistency and quality in large fabric dimensions, crucial in the home textiles market.

Air Jet Loom Maintenance: Ensuring Long-Term Efficiency and Reliability

Regular Cleaning for Air Jet LoomsImportance: Essential for preventing loom malfunctions and ensuring a clean operational environment.

Procedure: Implement a routine cleaning schedule focusing on dust-prone areas to maintain loom efficiency.

Benefit: Regular cleaning contributes to the loom's overall performance and durability, a key aspect in textile manufacturing.

Routine Inspections of Air Jet Looms

Importance: Crucial for early detection of potential issues, reducing downtime in textile production.

Procedure: Regular inspections should target critical loom components, a standard practice in maintaining weaving quality.

Benefit: Prevents major breakdowns, ensuring continuous and efficient fabric production.

Proper Lubrication of Air Jet Looms

Importance: Vital for the smooth functioning of the loom's moving parts, a must in loom care.

Procedure: Adhere to the manufacturers guidelines for lubrication to enhance loom longevity.

Benefit: Proper lubrication minimizes wear and tear, a key factor in maintaining operational efficiency.

Timely Replacement of Parts in Air Jet Looms

Importance: Key to avoiding unexpected failures and ensuring consistent loom performance.

Procedure: Promptly replace worn parts, a necessary step in proactive loom maintenance.

Benefit: Timely replacements keep the loom in top condition, crucial for high-quality textile production.

Operator Training for Air Jet Looms

Importance: Integral for the efficient operation and troubleshooting of looms, enhancing skill in textile machinery handling.

Procedure: Ongoing training programs ensure operators are up-to-date with the latest loom technologies.

Benefit: Well-trained operators are essential for maximizing loom performance and reducing operational errors.

Major International Manufacturers and Key Users

Toyota Industries CorporationHistory: Established in 1926, Toyota Industries Corporation began as a loom manufacturer and has since become a global leader in textile machinery.

Product Range: Known for innovative and efficient air jet looms.

Market Position: Renowned for quality and technological advancements in the textile machinery market.

Innovations: Pioneered in integrating advanced features like high-speed performance and smart technology in looms.

Tsudakoma Corporation

History: Founded in 1909, Tsudakoma boasts a rich heritage in the textile industry, specializing in weaving machinery.

Product Range: Specializes in high-speed, efficient air jet looms known for their durability and precision.

Market Position: A key player in the global market, respected for its consistent innovation and quality.

Innovations: Focuses on energy-efficient designs and advanced weaving technologies.

Picanol Group

History: Originating in 1936 in Belgium, Picanol Group has grown into a leading global player in the textile industry.

Product Range: Offers a wide range of advanced air jet looms, catering to diverse textile production needs.

Market Position: Recognized for its high-quality machinery and customer-centric approach.

Innovations: Invests heavily in research and development, continuously enhancing loom efficiency and versatility.

Dornier Weaving Systems

History: A division of the German company Lindauer DORNIER GmbH, known for its long history and expertise in weaving technology.

Product Range: Produces high-quality air jet looms designed for a range of applications.

Market Position: Esteemed for its engineering excellence and innovative textile solutions.

Innovations: Renowned for custom solutions and advancing loom technology to meet specific industry demands.

Sulzer Ltd.

History: With roots dating back to 1834 in Switzerland, Sulzer has a storied history in various industries, including textile machinery.

Product Range: Provides a range of textile machinery, including advanced air jet looms.

Market Position: Known for its durable and reliable loom designs.

Innovations: Focuses on sustainable and efficient production technologies.

Apparel Fabrication

Description: Air jet looms are extensively used in the production of a wide range of clothing materials, from lightweight shirting to heavier fabrics like denim.

Advantages: These looms are capable of high-speed production, ensuring efficiency in manufacturing diverse apparel fabrics. They also provide excellent fabric quality with minimal defects.

Home Textiles

Description: Ideal for producing home textile products like bed linens, curtains, and upholstery fabrics.

Advantages: Air jet looms offer versatility in handling various fabric types and weights, which is crucial for the diverse needs of home textiles. They also ensure high-quality output with consistent weaving.

Industrial Fabrics

Description: Used in manufacturing heavy-duty fabrics for industrial applications, such as canvas, tarpaulins, and geotextiles.

Advantages: These looms can handle the high strength and density required for industrial fabrics. They provide durability and consistency, which are essential for industrial use.

Technical Textiles

Description: Air jet looms are employed in creating technical textiles, which are used in various sectors like automotive, aerospace, and healthcare.

Advantages: Their precision and capability to produce high-strength, specialized fabrics make them ideal for technical textile production. They also allow for the incorporation of different yarn types, including synthetics and composites.

Automotive Textiles

Description: These looms are used in the automotive industry to produce interior fabrics for vehicles, such as seat covers, airbags, and upholstery.

Advantages: Air jet looms can efficiently produce large quantities of fabric with the required strength and texture for automotive applications. They also ensure the high quality and durability needed for automotive textiles.

Air Jet Loom Innovations: The Future of Fabric Weaving

Air jet looms have undeniably transformed the textile industry. Their introduction marked a departure from traditional, slower weaving methods, paving the way for mass production of diverse fabric types. The various loom designs, from cam to Jacquard, cater to a wide range of fabric patterns and complexities. Proper maintenance, including regular cleaning and timely replacement of parts, is crucial for their longevity and efficiency. The global landscape of air jet loom manufacturers, with giants like Toyota Industries and Picanol Group, reflects the international reliance on this technology. The applications of air jet looms are vast, extending from everyday apparel to specialized industrial and automotive textiles. This versatility underlines their indispensable role in modern textile production. As technology advances, we can anticipate further enhancements in air jet loom capabilities, reinforcing their position as a cornerstone of the textile industry.

�A loom in which the weft yarn is propelled through the shed by means of a jet of air.

Some more terms:

Mandarin Collar's Global Voyage: From Imperial Robes to Runways

Unraveling the Elegance: The Story of the Mandarin CollarWhen discussing fashion and textile milestones, the elegance and uniqueness of the Mandarin collar cannot be overlooked. A simple yet striking...

Read about Mandarin CollarRip-Stop Nylon: The Powerhouse Fabric You Didn't Know You Needed

A lightweight, wind resistant, and water resistant plain weave fabric. Large rib yarns stop tears without adding excess weight to active sportswear apparel and outdoor equipment such as sleeping bags...

Read about Rip-stop NylonSatin Nylon

This type of satin-finish material is usually made of nylon. According to one manufacturer, satin nylon is probably the most common satin fabric used in our industry. There are two types of satin...

Read about Satin NylonBactericide

Bactericides are chemicals that are used to destroy or inhibit the growth of bacteria. In the textile industry, bactericides are used to protect fibers and fabrics from bacterial growth and to...

Read about BactericideWilton Carpet

Wilton carpet is produced on a specific type of weaving machine called wire loom. Wilton carpets are pile carpets whereby the pile is formed by inserting steel rods in the pile warps of the fabric....

Read about Wilton CarpetEponge

A fabric of wool, also of rayon and silk. The name is derived from the French term eponge for "spongy". It is a very soft and sponge-like fabric in a variety of novelty effects with loose weave. It...

Read about EpongeLeader Strings

Leader Strings, also known as guide or tracer strings, are an essential component in the textile industry used for various purposes, such as measuring, alignment, and guiding during the production...

Read about Leader StringsAbdig

The term "abdig" refers to a type of fabric in the textile industry. It is a plain weave dress fabric that is commonly made with a cotton warp and a wool filling. Plain weave is one of the simplest...

Read about AbdigOn this page

Add a definition

- The term you want to define

- Its definition in 500 words or less

- Attach an image if necessary.

- Optionally, tell us about yourself in 200 words or less!

Companies for Air Jet Looms:

- Company name

- Company address

- Attach a logo, if necessary.

- Optionally, tell us about yourself in 200 words or less!

Italian textiles are often associated with luxury and elegance, making them highly sought after worldwide.

Italian textiles are often associated with luxury and elegance, making them highly sought after worldwide.