Last Updated on: 28-Jun-2024 (29 days ago)

Share on Facebook • Share on Twitter

The primary purpose of a hem is to prevent the fabric from unraveling and fraying, thereby extending the lifespan of the garment or textile. It adds durability to the edges, ensuring they withstand repeated use and washing. Additionally, hems contribute to the overall aesthetic appeal of the textile product by providing a polished and professional look.

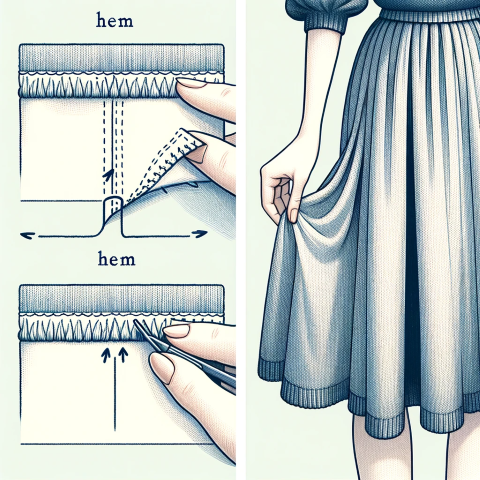

Hemming techniques can vary depending on the type of fabric, desired finish, and the purpose of the textile item. There are several common methods used to create hems:

Single Fold Hem: This is the most basic type of hem, where the raw edge of the fabric is folded over once and stitched down. It is often used for lightweight fabrics or as a preliminary step before applying more complex hemming techniques.

Double Fold Hem: In this method, the raw edge is folded over twice, creating a neat and enclosed hem. The double fold provides extra strength and a clean finish. Double fold hems are commonly used in clothing construction, especially for medium to heavyweight fabrics.

Blind Hem: A blind hem is a virtually invisible hem used on garments where the seam is not intended to be visible from the outside. It involves using special stitching techniques that catch only a few threads of the fabric, creating a discreet finish.

Rolled Hem: A rolled hem is a delicate and decorative hemming technique often used for lightweight and sheer fabrics. It involves rolling the raw edge tightly and stitching it close to the folded edge, creating a narrow, elegant finish.

Hems find applications in various textile products such as garments, curtains, tablecloths, napkins, and bed linens. They can be found on the bottom edges of skirts, dresses, and trousers, as well as the sleeves and neckline of garments. Hems provide structure to curtains, allowing them to hang neatly, and give a finished look to tablecloths and napkins.

Several textile manufacturers and users are renowned for their expertise in creating high-quality hems. While it is challenging to highlight all the top users or manufacturers, here are a few notable ones:

Fashion Brands and Designers: Prominent fashion brands and designers prioritize quality finishes and pay significant attention to hems. They often employ skilled artisans and seamstresses who specialize in creating impeccable hems, contributing to the brand's reputation for craftsmanship and attention to detail.

Tailoring and Alteration Services: Tailors and alteration services play a vital role in hemming garments to fit individual clients. These professionals have in-depth knowledge of various hemming techniques and use their expertise to ensure the perfect fit and finish.

Home Textile Manufacturers: Companies specializing in home textiles, such as curtains, bed linens, and tablecloths, incorporate hems to enhance the appearance and functionality of their products. These manufacturers often employ skilled seamstresses who meticulously craft hems to meet the demands of both aesthetics and durability.

Industrial Textile Manufacturers: Industrial textile manufacturers produce a wide range of textiles used in various applications, such as automotive interiors, upholstery, and medical textiles. Hems are often incorporated into these products to provide strength and durability, ensuring they withstand rigorous use in demanding environments.

In summary, hems are an integral part of textile construction, providing a polished finish while preventing fraying and extending the lifespan of textile products. They are utilized in a wide range of applications, from garments to home textiles and industrial products. Skilled artisans, fashion brands, tailoring services, and textile manufacturers all contribute to the utilization and advancement of hemming techniques in the textile industry.

�To hem a piece of cloth (in sewing), a garment worker folds up a cut edge, folds it up again, and then sews it down. The process of hemming thus completely encloses the cut edge in cloth, so that it cannot ravel. A hem is also the edge of cloth hemmed in this manner.

Some more terms:

Cambrian Tweed

Rough woollen fabric made in the uplands of Mid-Wales from the local hardy sheep. Plain weave, hopsack, or herringbone weaves are the most usual and the yarns are either dyed with synthetic dyes for...

Read about Cambrian TweedNapped

Napped is a dry, permanent finish in which fibers are raised from the fabric by bristled rotating brushes. This finish allows the fabric to provide more insulation, while also lowering its resistance...

Read about NappedJet Dyeing Machine

a) A machine for dyeing fabric in rope form and in which the fabric is carried through a narrow throat by dye liquor circulated at high velocity. b) A machine for dyeing garments and in which the...

Read about Jet Dyeing MachineOuting flannel

Outing flannel is a soft and lightweight woven cotton fabric that is often used in apparel and bedding products. It is typically brushed on both sides to create a fuzzy texture that is cozy and warm...

Read about Outing flannelShatush

This is one of the finest textiles. It is created from white, silver or gray hair of wild goats. The supply of this hair is very limited so the textile is very rare and it is one of the most...

Read about ShatushAlbatross

A lightweight, plain weave fabric traditionally of wool or wool blends with a napped, fleecy surface. So named because the texture resembles the breast of an albatross. Usually light in color- used...

Read about AlbatrossAxminster

A type of carpet where the pile is inserted one row of tufts at a time, each row representing a section of the overall pattern. The tufts are `U'-shaped, and are anchored at the bottom into the...

Read about AxminsterCap Sleeve

Cap sleeves are a popular style of sleeve in textile design that is commonly used in women's clothing. This sleeve style is characterized by its short length, which extends only slightly over the...

Read about Cap SleeveAdd a definition

- The term you want to define

- Its definition in 500 words or less

- Attach an image if necessary.

- Optionally, tell us about yourself in 200 words or less!

Companies for Hem:

- Company name

- Company address

- Attach a logo, if necessary.

- Optionally, tell us about yourself in 200 words or less!

The city of Jinhua in Zhejiang province is an important hub for textile and garment production.

The city of Jinhua in Zhejiang province is an important hub for textile and garment production.