Last Updated on: 07-Jun-2024 (1 month, 20 days ago)

Share on Facebook • Share on Twitter

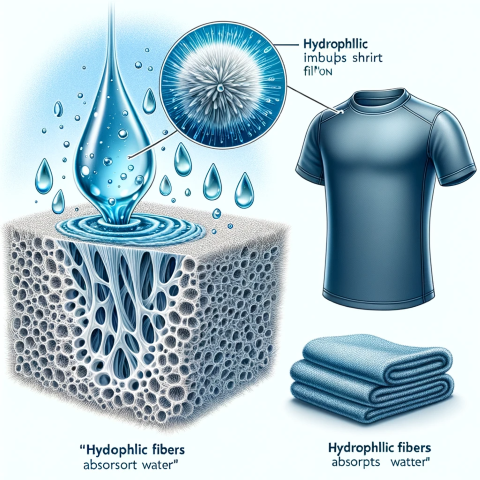

Hydrophilic Fibers: Enhance Moisture Management in Athletic Wear

Natural hydrophilic fibers include cotton, linen, and wool. Cotton is one of the most commonly used hydrophilic fibers in textiles due to its ability to absorb moisture and release it quickly, making it ideal for warm weather clothing. Linen is another natural hydrophilic fiber that is used in textiles due to its high absorbency and breathability, making it ideal for summer clothing. Wool is also a hydrophilic fiber, but its moisture absorption and release properties are slower than cotton and linen.

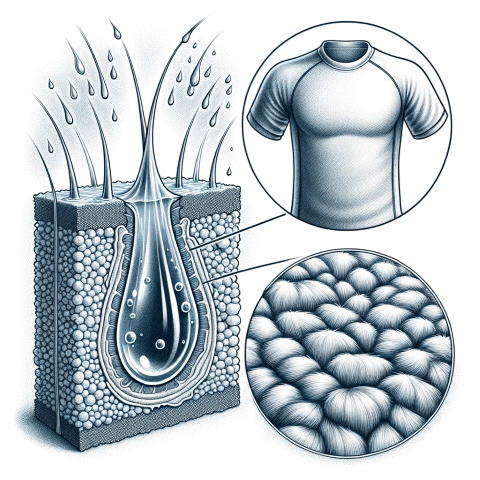

Synthetic hydrophilic fibers include polyester, nylon, and rayon. Polyester is a synthetic fiber that is widely used in textiles due to its durability and moisture-wicking properties. Polyester fibers are often blended with other fibers, such as cotton, to improve their moisture management properties. Nylon is another synthetic hydrophilic fiber that is commonly used in athletic wear due to its strength and ability to wick away moisture. Rayon is a semi-synthetic hydrophilic fiber made from wood pulp. It is known for its softness and moisture-wicking properties, making it popular for athletic wear and underwear.

Hydrophilic fibers can be treated with various finishes and coatings to enhance their moisture management properties. For example, moisture-wicking finishes can be applied to textiles made from hydrophilic fibers to improve their ability to wick away moisture. Antimicrobial finishes can also be applied to hydrophilic fibers to prevent the growth of odor-causing bacteria.

The use of hydrophilic fibers is particularly important in the development of performance textiles, such as athletic wear. Performance textiles are designed to enhance the wearer's comfort and performance during physical activity by managing moisture, reducing odor, and providing other benefits. Hydrophilic fibers play a key role in achieving these goals by helping to regulate the wearer's body temperature and keeping them dry and comfortable.

Hydrophilic fibers are also used in other applications, such as medical textiles and home textiles. In medical textiles, hydrophilic fibers are used in wound dressings, surgical gowns, and other products that require high absorbency and moisture management properties. In home textiles, hydrophilic fibers are used in towels, bedding, and other products that require high absorbency and softness.

Some of the top manufacturers of hydrophilic fibers and textiles include DuPont, Invista, Lenzing AG, and Toray Industries. DuPont is a leading manufacturer of synthetic fibers, including polyester, nylon, and spandex, which are commonly used in performance textiles. Invista is another major producer of synthetic fibers, including nylon and spandex. Lenzing AG is a leading producer of cellulosic fibers, including rayon and lyocell, which are known for their softness and moisture-wicking properties. Toray Industries is a Japanese conglomerate that produces a wide range of synthetic fibers, including polyester, nylon, and polypropylene.

In conclusion, hydrophilic fibers are essential components of textiles designed for moisture management, such as performance wear, medical textiles, and home textiles. The use of hydrophilic fibers, both natural and synthetic, is widespread in the textile industry, and their properties can be enhanced through the application of various finishes and coatings. Top manufacturers of hydrophilic fibers and textiles include DuPont, Invista, Lenzing AG, and Toray Industries. As the demand for performance textiles continues to grow, the development of new and innovative hydrophilic fibers will be crucial to meeting the needs of consumers and industries alike.

�Fibers that absorb water easily, take longer to dry, and require more ironing. Hydrophobic Fibers - Fibers that lack the ability to absorb water.

Some more terms:

Futon

A sofa frame featuring a large single cushion where the frame and cushion can be unfolded to use as a bed. The cushion itself is also called a futon and is sometimes used independently from a sofa...

Read about FutonNeck tape

In the realm of textiles, neck tape plays a vital role in providing comfort, stability, and aesthetic appeal to garments. This article explores the meaning, history, types, tips for handling, and...

Read about Neck tapeEnzyme Washed Textiles: The Green Revolution in Fabric Processing

Refers to the process of washing with a cellulase enzyme -one which attacks the cellulose in the fabric- giving it a used, worn appearance and a desirable soft hand. The effect is similar to stone...

Read about Enzyme washedBottle Bobbin

A bobbin that has a cylindrical barrel and a conical or flanged base, and from which yarn can be withdrawn over the nose, i.e. the top of the barrel. NOTE: The shape of the fully wound bobbin is that...

Read about Bottle BobbinSatin Nylon

This type of satin-finish material is usually made of nylon. According to one manufacturer, satin nylon is probably the most common satin fabric used in our industry. There are two types of satin...

Read about Satin NylonMoire Patterns: Weaving Waves into Textile Narratives

Silk, rayon, or cotton in a plain or crosswise rib weave. It has a watermarked finish that is fairly stiff with body in most cases. It is produced by passing the fabric between engraved cylinders...

Read about MoireTextured Yarn

A yarn that has been so processed as to introduce durable crimps (q.v.), coils, loops or other fine distortions along the length of the fibres or filaments. NOTE: a) The main texturing processes...

Read about Textured YarnBean Stitch

A type of running stitch composed of three stitches placed back and forth between two points. Often used for outlining because it eliminates the need for repeatedly digitizing a single-ply running...

Read about Bean StitchAdd a definition

- The term you want to define

- Its definition in 500 words or less

- Attach an image if necessary.

- Optionally, tell us about yourself in 200 words or less!

Companies for Hydrophilic Fibers:

- Company name

- Company address

- Attach a logo, if necessary.

- Optionally, tell us about yourself in 200 words or less!

The city of Madaripur is known for its growing textile industry.

The city of Madaripur is known for its growing textile industry.