Last Updated on: 25-May-2024 (2 months, 2 days ago)

Share on Facebook • Share on Twitter

Crease marks can occur during various stages of textile production, including weaving, cutting, sewing, and finishing. They can be caused by factors such as improper handling, incorrect folding techniques, or inadequate pressing. When fabrics are folded or compressed in a certain way, the fibers within the fabric become compressed, resulting in a permanent crease mark.

Textile manufacturers and garment producers strive to minimize and eliminate crease marks to maintain the visual appeal and quality of their products. Various methods are employed to prevent and remove crease marks during different stages of production. Pre-treatment processes, such as steaming or wetting the fabric, can help relax the fibers and reduce the occurrence of crease marks. Proper handling and storage practices, such as rolling instead of folding, can also minimize creasing.

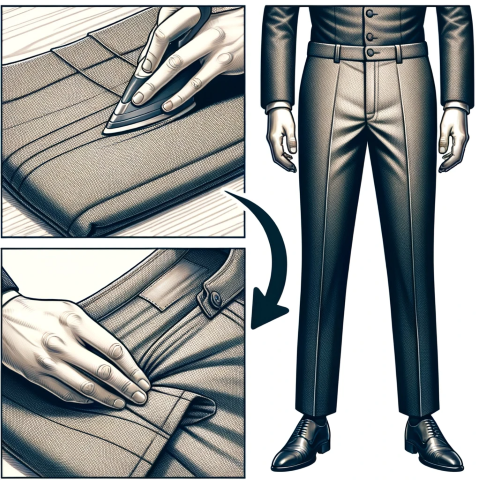

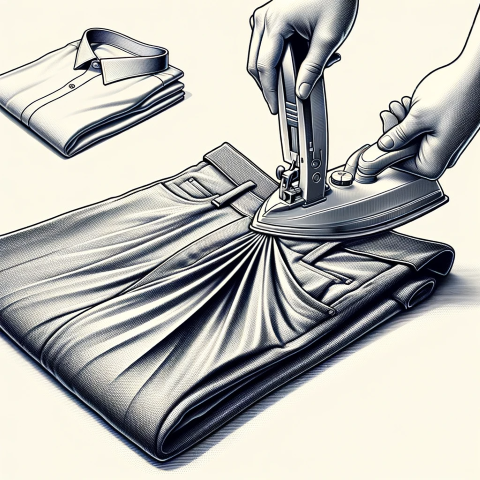

In addition to production techniques, there are also technologies and tools available to address crease marks. Fabric finishers and garment manufacturers may use steam irons, steam presses, or specialized machinery to remove creases during the finishing stages. These methods involve the application of heat and moisture to relax the fibers and reshape the fabric, ultimately eliminating or minimizing the appearance of crease marks.

The top users and manufacturers of technologies and tools to deal with crease marks in textiles include both large-scale industrial machinery providers and specialized fabric finishers. Companies like Veit, Kannegiesser, and Hoffman/New Yorker are well-known manufacturers of textile machinery, including steam irons, steam presses, and finishing equipment that aid in removing crease marks. These manufacturers offer a range of solutions for fabric finishing and wrinkle removal, catering to various sectors of the textile industry, from garment production to home textiles and upholstery.

Fabric finishers and service providers that focus on garment finishing and textile treatment also play a significant role in eliminating crease marks. These companies typically offer specialized services such as steam pressing, garment reshaping, and wrinkle release treatments. They work closely with textile manufacturers and brands to ensure that their products meet the desired quality standards and have a flawless appearance.

Furthermore, leading fashion brands and high-end textile manufacturers often invest in research and development to develop fabrics that are resistant to creasing. By utilizing innovative fiber blends or incorporating wrinkle-resistant finishes into the fabric, these companies aim to provide garments and textiles that require minimal ironing and are less prone to crease marks. They prioritize fabric performance and ease of care to enhance the overall customer experience.

In conclusion, crease marks are unwanted impressions or lines that occur on fabric as a result of folding or bending. Textile manufacturers and fabric finishers employ various techniques, technologies, and machinery to minimize and eliminate these marks during production. Companies specializing in textile machinery, such as Veit, Kannegiesser, and Hoffman/New Yorker, play a significant role in providing solutions for crease removal. Additionally, fabric finishers and garment manufacturers that offer services for fabric finishing and wrinkle release contribute to the elimination of crease marks. High-end fashion brands and textile manufacturers also invest in research and development to develop fabrics that are resistant to creasing, reducing the need for ironing and minimizing the occurrence of crease marks in their products.

Differs from crease streak in that streak will probably appear for an entire roll. Crease mark appears where creases are caused by fabric folds in the finishing process. On napped fabric, final pressing may not be able to restore fabric or original condition. Often discoloration is a problem.

Some more terms:

Bi Component Fibres

Fibres spun from two different polymers. The most common types are made from polymers which have different melting points and are used for thermal bonding. Another variant is produced from polymers...

Read about Bi Component FibresCombined Fabric (laminated fabric)

A fabric composed of two or more preformed layers, at least one of which is a textile fabric, that adhere closely together by means of an added adhesive or by the adhesive properties of one or more...

Read about Combined Fabric (laminated fabric)Pongee

A fabric made using a rib variation of the plain weave. The construction is characterized by having a slight ridge effect in one direction, usually the filling. Poplin used to be associated with...

Read about PongeeLondon shrunk cloth

London shrunk cloth, also known as "shrunk finish cloth" or "London shrunk flannel," is a type of fabric that has undergone a unique shrinking process to enhance its properties and improve its...

Read about London shrunk clothPuff printing

Puff printing is a specialized technique used in textile printing to create a three-dimensional, raised effect on fabrics. It involves applying a specific type of ink or paste to the fabric surface,...

Read about Puff printingThe Shirred Waist: Style and Comfort Combined

Shirred Waist: Enhancing Style and Comfort in TextilesThe shirred waist is a design element commonly found in various garments, adding both style and comfort to the wearer. This article provides a...

Read about Shirred WaistPiqué: The Textile Revolution in Sportswear and Casual Fashion

Piqu in Textiles: A Timeless Fabric Woven Into the Fashion FabricThe Origins and History of Piqu FabricPiqu, pronounced as pee-kay, is a weaving style traditionally used in the production of cotton...

Read about PiqueThe World of Staple Fibers: The Fabric Building Blocks

Short fibers, typically ranging from 1/2 inch up to 18 inches long. Wool, cotton, and flax exist only as staple fibers. Manufactured staple fibers are cut to a specific length from the continuous...

Read about Staple FibersAdd a definition

- The term you want to define

- Its definition in 500 words or less

- Attach an image if necessary.

- Optionally, tell us about yourself in 200 words or less!

Companies for Crease Mark:

- Company name

- Company address

- Attach a logo, if necessary.

- Optionally, tell us about yourself in 200 words or less!

Fashion designer Zandra Rhodes is known for her bold prints and bright colors.

Fashion designer Zandra Rhodes is known for her bold prints and bright colors.